HK 1/32 A-20G Havoc

Big plane…need more olive drab…

Certainly looks a nice kit. I haven't done an HK kit yet and really want to do one but which is the hardest part!

It "feels" like a light-weight Zoukei-Mura kit. A lot of detail but in this case, the detail isn't as sharp or as complete as them. It needs some aftermarket for the cockpit, the bomb bay doors and the rear aircraft entrance hatch. Hardest part... dunno just started but have spent a lot of time trying to figure what I can combine before painting. I think as I go along the hardest part will be lining up all the interior bulkheads and making them all fit when I close up the fuaelage. Best part of this kit is the detail in the bomb bay area and exterior molded skin...it looks like real stressed aluminum.

I always tape up the large bits to get a sense of what I'm working with. You can't possibly get diehdral wrong with HK's but the join of the horizontal stabilizer is loosy-goosy and will need heavier glue to hold in place. It's almost exactly the length and has a similar wingspan to the HE 219 I just finished but not nearly as fragile as that was/is. Big boy...but I don't see this as overly difficult and you have a choice to heavily detail in areas you'll never see again. Good news is cockpit, wheel wells, engines, turret and bombbay are are highly detailed so you can afford not to do a ton of work inside the plane if you choose.

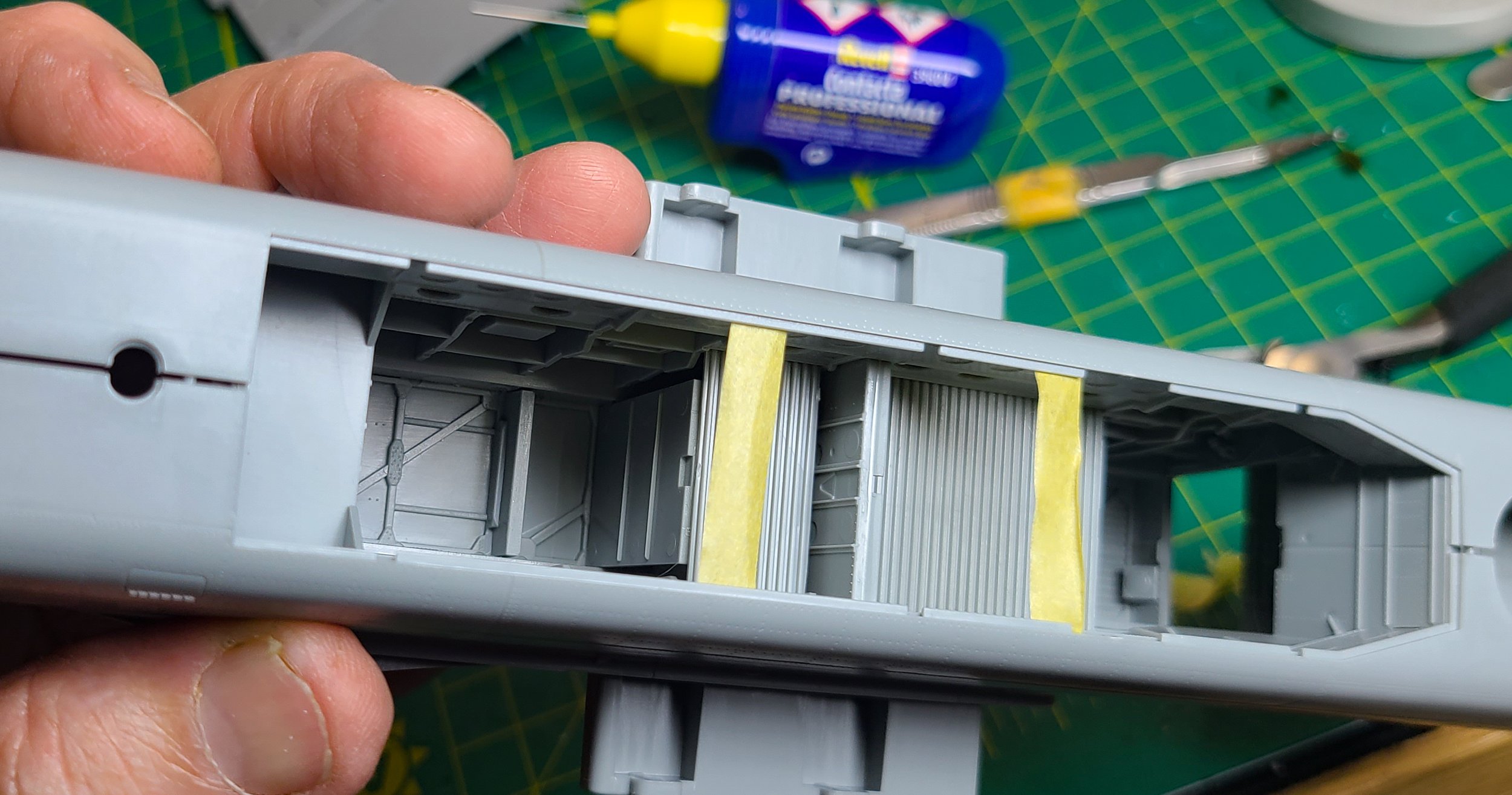

So if you decide to buy this I recommend dry-fitting all these interior components before you start your builds...good way to see how stuff fits, good way to see what needs to be painted and maybe what you can avoid given a lot of this area cannot be seen once assembled. They are fiddly and there's little tolerance for burrs, thick paint, etc.

I found, during dry-fitting the bomb bay area, that there's a fit issue here...where the rear bulkhead meets the lower tabs of the bomb bay assembly. I had to increase the size of the hole and decrease the size of the tab to get it to fit. On the bulkhead it looks like there's an outline around the hole where the tab goes...so maybe the hole wasn't fully opened.

There are also parts that have lightning holes that are not drilled out...but if you do drill them out be careful because some of them, on the other side of the plastic, have fuselage attachment points. This pic also shows me sanding down those attachment points so i could fit them in the rear bomb bay bulkhead.

I also recommend fitting the floor of the cockpit to the upper wheel well assembly and dry fitting the two sides before attaching the rear cockpit bulkhead...then fit that assembly into the aircraft to use the fuselage assembly like a jig to get the right slant on that rear cockpit bulkhead

I found out Airscale has a pre-order for a detailed cockpit layout so i ordered that and will not continue on the build as I was doing...but rather start to work on all the molded panels they made for this. Instead of adding glued on detail to each fuselage wall, they molded in a lot of the detail. These are the left and right sides of the front nose gear internal walls. Just a slab of plastic. I black-based, I sprayed thin coats of interior green followed by lighter coats on the panels, painted in the details with gray, silver, and a lighter interior green as highlights, gave it a Flory wash and some pigment work to lighten up the bottom half (dust)...that didn't hold very well when I sprayed on a matt finish so I'll get some pigment fixer to correct that issue. I added in some placards to give it some character (the model has a lackluster amount of decals...almost zero detailed ones on the outside, in the cockpit, etc...so aftermarket and Onemanarmy stencils will be the go-to route). The bomb bay is arguably the best looking ww2 bomb bay ever put to plastic so there will be a lot of painting there to give it a good look (even if you can't see hardly any of it w/o mirrors and torches (as the Brits say).

Working on the bits I can work on in the fuselage (waiting for the Airscale cockpit set). I'm rushing it a tad so there will be re-work here but overall it's coming into focus. Some hints:

There are multiple points where the two fuselage halves need to line up (front cockpit parts, front landing gear, entire bomb bay, rear bulkheads). Recommend you glue in the two bulkheads near the turret on the port side and use the fuselage halves dry-fitted together as a jig until the glue is set on that port side. Then do the last two bulkheads following the same advice. If you do it this way everything will align when you put the entire fuselage together/forever.

Rough draft as I still have a LOT of touch-up and paint-fixes here...but it's taking shape.

Since most of the detail is hidden right now (maybe the aftermarket will add in some additional hatches and detail for the stuff like the avionics shelf), i wanted to display this like I did my Uhu...with the rear gunners hatch open. Base issue is the hatch in the kit is just a flat piece of plastic. No stairs like the original. So I scratch built one semi-based on some boneyard pics of A-20's I've found (it's really hard to find good pics of the gunners compartment and the hatch/door/stairs). Just some thin plastic card and I found a few parts on a Eduard 1/32 Tamiya Zeke aftermarket part (engine I think) that I was able to piece together a reasonable looking set of support arms. I'll weather it up a tiny bit but this goes in a storage cup until near the end of the build.

Found an error in the manual and a cool thing...

Error first:

Both steps 36 and 48 have parts N15 and N16 (respectively) going into the slot that parts N21 and N22 are supposed to go into (respectively). There's another slot adjacent to them that those parts (N15 and N16) are supposed to seat into (the plastic cutout is there for the notch on the part).

So in this pic...N15 is showed as slotting into the slot that eventually N21 is supposed to go. The slot for N15 is on the other side of that actuator arm...it's where I put the blue arrow below.

Also...this is part of a complex landing gear assembly I suggest builders build using the lower wing section where the landing gear slots into, as a jig to help line up the attachment points and keep everything trued-up. Also...putting the nacelles on temporarily will help hold the gear in place while it dries.

As to a few cool things. I saw that Airscale has a pre-order for a replacement instrument panel and so I ordered one and posted about it on the HK Model Page on Facebook:

I found out Airscale has a pre-order for a detailed cockpit layout so I ordered that and will not continue on the build as I was doing...but rather start to work on all the molded panels they made for this. I will be a lot of painting there to give it a good look. https://www.airscale.co.uk/store.html...

Airscale then replied with this:

airscale wouldn't want you waiting too long Wes, so I have sent a pre-production PE fret (no decals) in advance of your order being sent at launch

Pretty cool...as to the build...I've finished off the nacelles, glued the wings together, got the main landing gear assembled, more or less finished the interior other than the instrument panel and turret. Need to finish the nose assembly (with all the guns), the engines, and slap it together and start in on the exterior paint job. So far I have to say easy kit to build, lots of detail you unfortunately cannot possibly see, really well molded parts, decals are seriously lacking (why I asked Sven at 1manarmy for stencils...but he doesn't have time to make one for now), it fits really well (best wing-to-fuselage mechanic of any manufacturer), and the instructions are...minimalist (biggest issue w/manual is they really didn't do a good job w/paint call outs...not enough detail).

All that said...it'll look great next to my other 1/32 planes.

ColinAtkins wrote:

Nice work putting that cats cradle of an undercarriage together Wes, did you mention to HK models their error on the instructions and good on them for being so helpful to their customers.

I did...they responded that they were already aware. I suspect one of the pre-release modelers who got the kit notified them (I did not get a pre-release kit...some store accidently sent me this early). As I've stated before HK has a great wing-to-fuselage mechanical design that all but eliminates any wing-root issues w/regard to fit. Only caveat I would add here is make sure you glue the wings near the root w/extra care...make sure the weld is tight inside the wing. On the shot below where you see the inside of the wing make sure those top and bottom join area's are welded shut. After I built the wing and connected it to a fuselage half, I noticed the middle section of the wing would flex a bit up so the join at the root wasn't flush w/fuselage. I used clamps and spread glue liberally around those top and bottom joins just inside the wing (at the leading and trailing edge) and let it dry for a night.

The core plane was developed in the late 30's and they went with a truss design where the truss was attached to the wing root area and the landing gear strut attached to that. So it's a bit bonkers looking. They followed the same design w/A-26 Invader. The book I got for this particular model has pages and pages of detailed notes on how everything works in these planes and it's a wonder they ever got off the ground much-less took damage and had to get fixed. The A20 also had a pretty dismal accident rate...one of the highest in the theater. It was one of the first American fast attack bombers of the war and as such was in great demand...but that speed ended up requiring thousands of fixes applied over the years.

Few more construction hints...almost all the parts fit really well together. There are some exceptions that are minor.

Most of the tail surfaces that came with my kit were slightly warped. Probably due to heat so use clamps (minor design nit...the tail surfaces, where the join at the trailing edge are pretty thick).

The male end of the vertical stabilizer might be a tad taller than the slot it fits into on the tail assembly...I had to sand mine down.

It's easy to loose track of which engine you are working on.

Good news...same parts for both sides.

Bad news...the firewall looks like it's the same but not. I ended up gluing mine in on the wrong side and had to do some surgery to correct that.

Semi bad news (depends on how you take this...there are more than 75 parts PER engine...easily the most part-intensive section of the build. Cutting out all those rocker heads...

Sad thing...this planes engines sit close to the front end of the cowl and as such demand a good wiring harness...I CAN'T FIND ANY YET. Hurry up Eduard...please?

Best thing...these are really good looking engines and the detail is solid. Worst thing...have fun w/exhaust.

Christian wrote:

Great work so far, keep up the amazing build thread so I can refer to when I build mine 😃

Thx...something I didn't add...there's a battery box behind the pilots area that has these two pipes coming off them that serve the same purpose as in your car...positive and negative cables off your car battery. Only problem I had was I kept breaking them off whilst dry-fitting the cockpit into the airframe when the bomb bay compartment was in as well (they share a wall). The other sad fact is they can't be seen once the ship is closed up if you put bombs in the front bomb bay. So much of this kit is closed off from normal view. It begs to be put on a mirrored base and to have mini led's put in the rear gunners compartment.

Engine work. Decided to not add wires for now...hopefully i'll be able to add wires later. Here's the interesting part about these engines...very detailed, exhaust and rocker arm covers are super fiddly but only because there are so many of them to do. The rocker arm cover is a new design i have not seen before (they way they model it). They do not mold the rocker arm covers (those bumps on top of the cylinders) into the cylinders...they are separate...all 28 per engine separate. What I found is your best bet here is to:

Paint the engine parts in step 28 and assemble them (I used Surfacer 1500 then AK Steel and then used Tamiya black panel line wash on the cylinders, then polished them w/AK Gun Metal polish pigment...did the same for the rocker arm covers )

Keep the rocker arm covers on the sprue and paint them...but first cut the sprue so there's all seven of them on one section that are all the same (once you get the kit you'll understand that)...that way you've already cut one of the sprue connection points off the cover before painting

Paint, cut them off the sprue, glue them to the cylinder heads, touch up spot paint as necessary.

NOTE: There are small male connection points on each of the rockers themselves that are supposed to fit inside the rocker arm covers but I've found they cause the rocker arm covers to ride up when glued on. So I took a pair of sharp cutters and carefully cut the connection points off all the rocker arms (they are super small)...that way the rocker arm cover would settle down on top of the rocker arm at the right angle when glued to the top of the cylinder.

The cowling is so tight I'd advise only to detail the front of the engine (if so desired). They do not come with any other detail behind the engine cylinders and exhaust. However, they look great as-is OOB. I will say...if you want to super-detail the engine and build engine cowlings that open up could not do too much better than these to start with (Although the full-size Resin2detail engines mentioned above are beautiful and you could go nuts w/this aircraft in the DIY arena).

Each model engine has 64 parts. 14 exhaust tubes + 14 intake tubes + 2 ignition tubes + 28 rocker covers + 2 rocker arm assemblies + 2 cylinder banks + 1 front gearbox + 1 heat shield...almost all of that is hidden underneath each engine cowling. There's no supercharger or anything back of the exhaust system. I think the casting is sharp and detailed but they could have done so much more here that I hope the aftermarket people pick up on. For those of you getting the model...a word of caution w/all those tubes. I was worried about loosing track of which one goes where so I sprayed them all on the sprue, cut the first one out, trimmed it a bit, glued it in position and repeated that process for the rest. After everything was in place I touched up all the tubes w/steel (AK) and manipulated the ends of the tubes so they look ok on the actual nacelle (dry fit the engine assembly on the nacelle/wing). I did not weather or do any additional work on the back end other than put a drop of black on the exhaust endings and I will weather the very ends of the tubes to get them sooted up. Unless you're a bit over-the-top...no need to go nuts on the backside of the engine assembly...i even left in some seam lines.

If someone creates an aftermarket engine I will go to town on that w/second A-20 I have coming....not here though.

Waiting on the Airscale instrument panel but got most of the rest done. The turret is another example of a well designed component that's just missing a few tiny bits to make it perfect... basically there are no bullets, no decals for the gunners controls, the ammunition boxes are not solid (more on that later) and the gun barrels are a bit underwhelming.

Aftermarket should go crazy here because you can display the entire turret outside the body of the aircraft and that then gives you a good look inside. It would not be that hard to make a DIY turret stand like you see in the picture below. I found some pics of a restored turret and control set and added some placards and wiring to the turret to give it a splash of interest and bought a set of brass barrels that are due in a few days.

Additionally, the ammo boxes had an empty back but that back is exposed so I used milliput to fill it in and sand it out (you need to do this if you're going to display the turret outside of the aircraft). You can also see in that second pic the radio deck...that's another area aftermarket could really make a huge difference. All those electronic devices are hidden under the fuselage and cannot be seen. That's unfortunate because on the real aircraft a part of the fuselage top hinges up and away (like the cockpit) to expose the entire deck. Give a modeler an electronics bay and a good one will go insane with detail (look at the F104 or other modern jet examples).

And finally...the last pic is important. I neither have the nose gear nor gun bay in yet, but do have a majority of the parts on the rest of the model and it looks like the nose weights will keep the model on it's three wheels and not fall back onto it's tail.

It's clear to me that if I was to paint it to match the actual "Miss Laid/La France Libre" it might be a bit too much...here's some examples...

You can also see where they painted over the entire nose sheeting as the "Miss Laid" wasn't politically correct and it was changed to "La France Libre" for a ceremony (with French officials) marking it's 100th mission over Germany (you can still see the "Miss Laid" underneath if you look carefully enough). Also just noticed the tires here are diamonds...the model has simple straight-tread tires.

Anyway...decisions, decisions.

Artscale is going to release a resin seat and resin .50 cal barrels (really needs these) and heard that 1manarmy is working to get a stencil out this August. The dearth of detailed decals on this kit (outside of the major ones) is a clear subtraction from a great kit but I'm sure the aftermarket will kick in here. Given the A20 was first used in Europe by the RAF and also in Australia...I have to think the demand for this model is solid. Outside of the Mossie, wouldn't this have been the next best light/medium bomber in use by the RAF (at least in numbers)?

Anyway...making progress. I just ordered some GasPatch 50cal belts because although the nose section looks detailed as you build it...it's not outside of the guns and the ammo boxes. There are only facsimiles of one ammo tray on each side (the one you see in the photo)...and if you open the nose up for inspection...it's pretty bare. They were crammed with the ammo feeds going from the ammo boxes to the guns. Think how Tamiya did their nose guns on the Mosquito. Room for improvement here.

BTW...those shiny things just inside the cockpit are the weights. Once the nose goes on it balances nicely.

I really like the kit but sometimes they make decisions that seem baffling. Here's a case. There are two side mounted .50 cal's on each side of the nose cone. See where the injector pin is? Right smack in the middle of an otherwise beautifully rendered piece of plastic on the side exposed to the open hatch. I'm not sure why they didn't put us on the other side where you can't see it.

Slow go right now awaiting Gaspatch .50 ammo belts and the Airscale instrument panel (the model will go together quickly after that as most of it is done) but for the first time figuring out how good AK metal-based pigments are. The guns are just sprayed w/Mr. Surfacer 1500 and after a day to let the primer set in, I just dry brush the Gun Metal AK pigment all over it. It's quick and it looks reasonably well. I also used their metal pigment on the propellor hubs after painting them in AK Real Metal Steel.

Also a quick and easy way to do the prop markings (at least the ones on the end). paint blades, like guns, w/Mr. Surfacer 1500. After priming, tape them all up as shown (both sides)...gives you a punchers chance of lining them all up evenly. Spray white on an angle slightly below and swipe up as you spray (keeps paint from getting down the sides where there are gaps in the tape)...thin coats...never let your paint get "wet". After the white dries, tape that center area over and go w/yellow (I use RLM04 because it looks better and more accurate to me) and repeat thin/never get wet paint. Remove the tape fairly soon after painting and weather as you choose.

Waiting on parts makes me spend more time on details than I would otherwise so it gave me some time to weather the props (I broke a blade on the other so it's in traction right now). I still need to do salt-weathering and another dust pass to get more variations in the black. I had some trouble w/these decals and will need to pull some from the second kit I have. They are Cartograf...but once one of them folded up against itself, I could not get it pulled apart. I ran a 95-5 percent thinner to dark grey over the leading edge, scabbed at the front edge of each blade w/mechanical lead pencil (need to add more scuff marks) and then lightly sanded each blade to smooth any edges. The salt technique will make the black look super used and stained. The more I study these A-20's from books and the web...the more I notice other than the camouflaged Boston's, I don't think A-20's were EVER cleaned. They flew them until they crashed, were shot down, or fell apart.

What could possible go wrong here...

Still waiting on Airscale...but gave me time to order the Master B-17 brass barrel set and some .50 cal resin ammo belts from Gaspatch to get more detail into the turret.

Stephen wrote:

Turrets looking great wes

ColinAtkins wrote:

The turret certainly looks the part Wes, very nice indeed.

Steven wrote:

Lovely turret work Wes.

It's honestly some of the best work HK has ever done...not just the turret but the entire kit...although the gaspatch ammo belt really sells the turret and I'm going to add some to the nose gun bay. This model screams "build me a British North Africa aircraft maintenance revetment diorama". Once the aftermarket really kicks in, you'll see radio shelf, motor, landing gear, and rear gunner area resin kits that will take this to a higher level. One item that might give people trouble is the front landing gear is super-spindly and this is a heavy model to support. The good news is the balance is so good that there's actually not a lot of weight on the nose wheel...it's CG is a bit back towards the nacelle landing gear.

BIG HINT: Do not build the nose landing gear until the last possible moment (as you put the two fuselage halves together)...it'll break on you in a heartbeat.

ALSO FOR DISPLAY: It's not that big a model for 1/32...don't let it scare you off as a shelf-space monster. It's as big as a 1/48 four-engine bomber in terms of space (almost exact dimensions of my He 219).

Don’t look at this next picture…it’s for another build that’s still on the shelf.

A short video on some new PE parts that Eduard came out with. If you get this kit a combination of Airscale and Eduard would be a smart move. I think the Eduard instrument panel and especially the resin wheels are really good. BTW...in case you're asking...i get zippo from anyone to make these...I just like the work. Model and video making have similar skill sets I think.

Got in several cockpit PE kits and went w/combination of parts from each. Some Eduard and Airscale in here. Glued the two halves of the fuselage together last night so I'm done with all the major sub-assemblies (nose guns, fuselage, wings, engines, undercarriage). Only need to prime, sand, and start the overall paint scheme (Miss Laid w/invasion stripes). In Sep my wife and I are going to Colorado for a three-week vacation, and I aim to get this done before that.

Got it all primed. I have two kits (as mentioned earlier) so I occasionally rob the second kit of some parts...in this case I'm using the canopy on the second one as a blank/paint mask for this one. If ANYONE here buys this kit and needs some parts...let me know. Glad to send them.

BTW...this is the easiest model I've built in terms of handling. What I mean is almost every other model I've handled in-and post-build feels fragile, and I have to be careful not to break anything or have it fall apart in my hands...this model feels solid when built and insanely easy to handle during build. Maybe it's the modular nature of the build...or how the wings attach so you NEVER have to glue them and can take them off and on as you need too...plus the slab fuselage has a lot of places you can grab it without feeling like you'll break something. Of course, it'll get harder to hold as the gear and bomb bay doors are in place, but for now it's been a dream to build.

Finished up base painting. Thinking of buying a Circuit to make my own masks because for now, I can't find a mask set that includes the large insignias. MONTEX 1/32 Tamiya Corsair masks work...but that only gives me the insignias and not the other markings. So after silvering it, I used red brown, olive green, and some tan sprayed over templates to add the imperfections and then added thinned olive drab over it in various thicknesses trying to be random by painting one section, jumping to another, jumping back to a previous section, etc.

Did the bottom the same way but was a bit too heavy on the paint...might have to revisit some weathering there to make up for it.

I made a couple of mistakes: At one point dropped so much alclad on it in one area it melted part of the plastic and I had a sanding and panel line exercise…and when I pulled the masks off the grey camo lines...it ripped all the paint off those side armor panels made of brass so I had to repaint them.

But it's coming together nicely.

Yea...busted the prop and the weathering here was done by simply dabbing on canopy mask on the area's you see silver and then using a brush w/water to remove what I wanted.

Nigel Frampton of Nigel's Modelling Bench asked me in a Facebook post if I thought there were balance issues w/model and I thought a short video could show better than tell.

Been on a three week vacation to Colorado for hiking, touch grass, and other healthy pursuits...but now back and working to finish this off. Had a scare with trying to do painted on insignia's...i screwed up some painting and had to fix a bunch of stuff and at that moment decided to stick w/decals for the larger insignia's and I'm glad I did. The Cartograph decals in this kit are pretty much excellent. They lay down really well and other than a thin outline they could almost pass for paint. I have the invasion stripes going, main decals and this weekend will be adding all the small markings using 1manarmy's stencil kit for this model. This really is a great model and HK's best so far.

I think the screwing up painting the insignia's thing will be my big glitch on this build. It was scary because I screwed up the invasion stripes and had to scramble to hide the disaster. The smaller stuff I've screwed up (broke off part of the tail antenna, broke the front landing gear, broke TWO propellor blades, slightly mis-aligned the nose) will be ok and/or I've fixed it or will refuse to take a picture from that angle where you see it). It is coming together nicely. Once I get the major decals done I have to finish up the canopy, the gear and bomb bay doors, put a few brake lines in, build out the aerial antenna, open up the rear door (so you can see the .50 cal), finishing paint, a gloss coat, oils and exhaust stains, and a flat coat to finish. It's been a slow build but only because of a three week vacation and other weekend responsibilities keeping me from building. Might get done by mid-week next week...or not.

So...Flory Sand (bottom) or Flory Dark Dirt (top)? After wards it'll all get a buff and flat coat to seal in everything...so any "shine" you see here will be greatly muted.

Almost done. Minor work. Maybe finished by weekend but still waiting on Eduard wheels/tires.

Glen Wilson wrote:

Looks great. Going to have to look at how you did the chipping for when I get to that stage.

Yea...it's waaay overdone (lol)...but I enjoyed the process and there are some pics of this aircraft that the chipping wasn't as rough but the variations in the paint were a lot rougher.

From the start...Mr. Surfacer 1500 (black), Alcad Dark aluminum, clear coat, mottled the entire plane with various brown and green splotches using random templates, used torn foam to apply Abteilung 502 Liquid mask (like dry brushing) on the leading edges of wings, cowlings, etc, painted the entire A/C in Olive Drab (Tamiya) but at varying degree's of thickness...in some places leaving a lot of the mottling to show through, then pealed off the mask. Repeated the process somewhat for the stripes knowing they were painted on regardless of the wear on the aircraft...used liquid mask again then painted the stripes. Pretty easy to do...just have to figure out the layers ahead of time.

Finished up. Added the antenna's, affixed the gunners hatch in the open position although there are issues there, cleaned up some minor painting mistakes although there's a few that look like wear-and-tear so I left them in. Still need new resin wheels and hopefully be able to get HK to ship me a few spare parts so I can also build a cockpit open version.